In the high-stakes world of construction, every decision is weighed against its impact on the budget, timeline, and safety of the project. Project managers, purchasers, and operations directors operate under immense pressure, navigating razor-thin margins, tight deadlines, and increasing regulatory scrutiny. In this environment, adopting new technology is not about innovation for its own sake—it’s about a clear, undeniable business case. The Infinity Cube, a state-of-the-art Battery Energy Storage System (BESS), presents exactly that: a strategic investment that delivers measurable, multifaceted returns in cost savings, operational efficiency, and on-site safety.

This guide moves beyond the technical specifications to detail the tangible business advantages of integrating the Infinity Cube into your operations. We will demonstrate how it directly enhances project profitability, streamlines complex workflows, and fundamentally mitigates operational risk, making it an essential component of the modern construction playbook.

The Financial Advantage: A Deep Dive into Cost Savings

The most compelling argument for any new technology is its ability to reduce operational costs and drive profitability. The Infinity Cube excels here, offering both immediate and long-term financial benefits that fundamentally change project economics from day one.

Upfront & Long-Term ROI

While the transition to clean energy might seem daunting, the Infinity Cube offers significant upfront cost savings by reducing the need for extensive traditional energy infrastructure. This means less capital investment in multiple, oversized diesel generators, complex cabling, and large fuel storage facilities. Furthermore, as governments and industry bodies push for greener practices, adopting energy-efficient equipment like the Infinity Cube makes companies eligible for a range of financial incentives, such as tax credits, grants, and subsidies, further lowering the initial barrier to entry. This proactive approach also significantly increases the chances of winning project tenders that have stringent sustainability and carbon reduction requirements.

The long-term return on investment is where the financial case becomes undeniable. By storing energy from the grid during off-peak hours when electricity is cheap and deploying it during expensive peak demand periods—a practice known as energy arbitrage—construction projects can drastically cut their monthly energy bills. The savings are compounded by a dramatic reduction in maintenance costs. Unlike diesel generators that require constant upkeep, oil changes, and part replacements, a BESS has far fewer moving parts, leading to higher reliability and lower long-term maintenance expenses.

For applications with alternating loads, such as powering tower cranes or passenger hoists, the hybrid mode provides game-changing savings. By synchronizing with a smaller, more efficient generator to handle only the base loads, while the Infinity Cube handles the peak surge loads, it enables generator downsizing to remain off for most of the day. This simple yet brilliant function can reduce diesel costs and emissions by up to 80%.

Case Study Snapshot: TeamBuild HDB Project

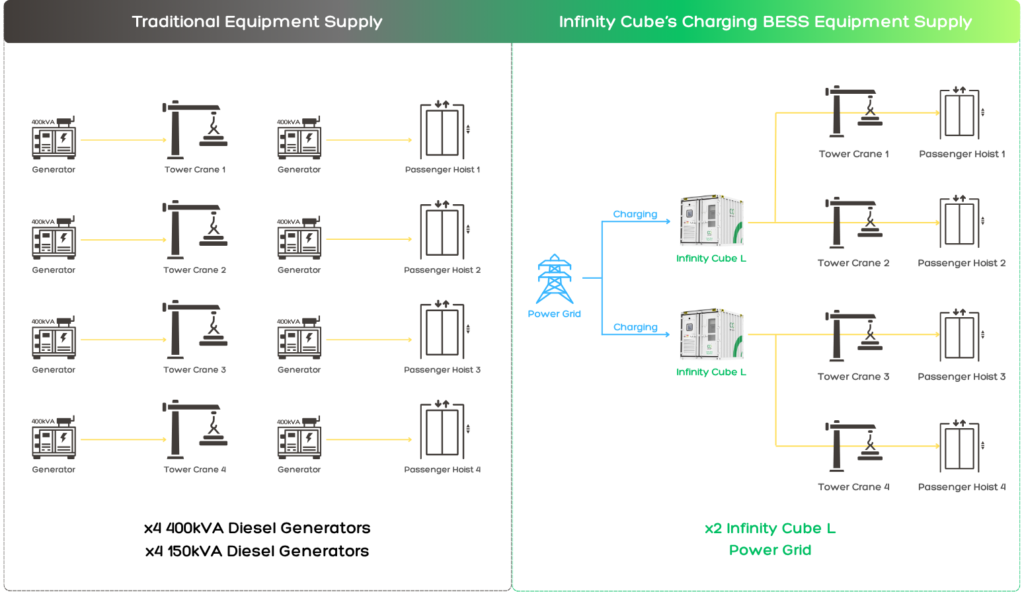

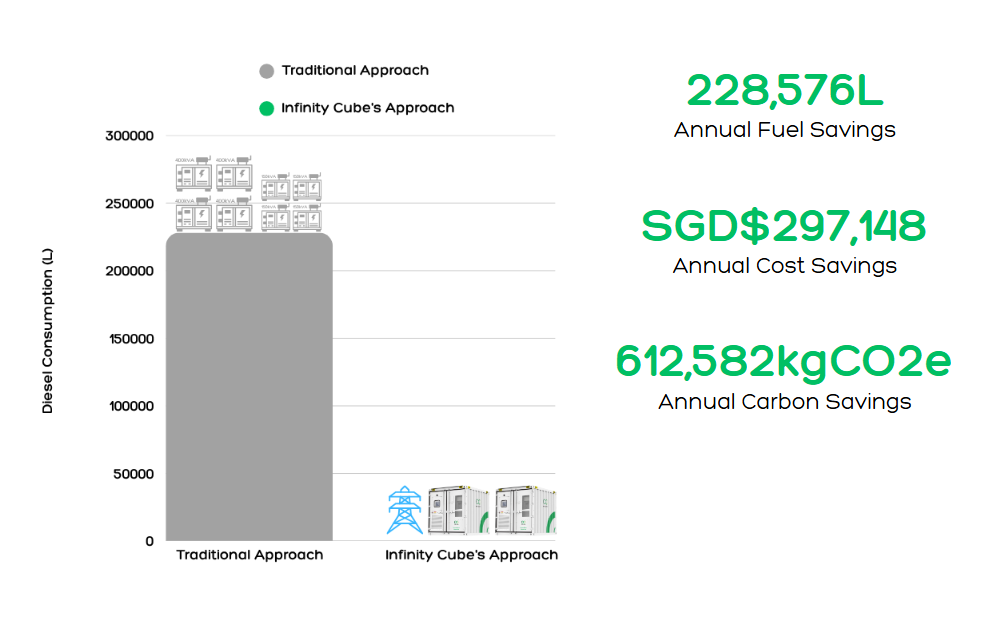

In a large-scale HDB project, TeamBuild Construction Group faced the challenge of powering four tower cranes and four passenger hoists simultaneously. The traditional approach would have required eight separate diesel generators. By replacing this entire fleet with just two Infinity Cube L units charged from the grid, TeamBuild completely eliminated the need for diesel on site, achieving remarkable annual results:

- SGD$297,148 in Cost Savings

- 228,576 Liters in Fuel Savings

- 612,582 kg in Carbon (CO2e) Savings

Driving Operational Excellence: Enhancing Site Efficiency & Resilience

Beyond direct cost savings, the Infinity Cube streamlines site operations, reduces workloads, and builds a powerful layer of energy resilience, ensuring projects stay on schedule and run smoothly even in challenging conditions.

Automated Power Management & Reduced Workload

The Infinity Cube is equipped with a smart Energy Management System (EMS) that acts as the central brain for your site’s power, revolutionizing management and reducing the burden on your team.

- Intelligent Load Balancing: The system automatically stores surplus energy during low demand and releases it instantly to manage peak times. Imagine a tower crane, multiple passenger hoists, and site office all running simultaneously. The EMS seamlessly balances these loads, ensuring a stable, uninterrupted power supply that prevents waste and protects sensitive electronic equipment from damaging power fluctuations.

- “Set It and Forget It” Automation: The EMS seamlessly and automatically switches the load between the battery, grid, or a generator as needed. If a battery is running low, automatic charging kicks in below a set state of charge, at the same time, it ensures a smooth, instantaneous transition to another power source without any manual intervention. The entire system can be remotely controlled and monitored from the comfort of the office, freeing up your on-site team to focus on critical construction tasks rather than manually managing power.

- Accurate, Actionable Data Tracking: The EMS provides precise, real-time data on energy consumption, power quality, and diesel usage (in hybrid mode). This data is crucial for accurate project management, budgeting, and, increasingly, for mandatory ESG (Environmental, Social, and Governance) reporting. This detailed tracking provides a verifiable record of your project’s carbon footprint, a powerful asset for future project bidding.

De-risking Timelines with Energy Resilience and Reliability

In construction, time is money. Unexpected power disruptions—whether from grid instability, extreme weather, or fuel delivery delays—can derail a project timeline, leading to costly overruns. The Infinity Cube is the ultimate solution for energy resilience, effectively removing these variables from the risk equation.

- Uninterrupted Backup Power: In the event of a grid failure, the BESS provides an instant and seamless backup power supply. This isn’t just a convenience; it’s a safeguard against the immense financial and logistical impacts of downtime, keeping your project on track and your workforce productive.

- Simplified Logistics: The ability to run fully on stored battery power for extended periods eliminates the need for constant diesel top-ups. This simplifies on-site logistics, reduces the traffic of heavy fuel delivery trucks, and removes the entire complex supply chain of ordering, storing, and managing liquid fuel.

Mitigating Risk: A Foundational Commitment to On-Site Safety

Safety is the most critical, non-negotiable aspect of any construction project. Advanced BESS technology provides a demonstrably safer alternative to traditional diesel generators by methodically designing out risks associated with fire, electrical hazards, noise, and fuel handling.

The Infinity Cube is engineered with multi-layered, cutting-edge safety features:

- Integrated Fire Suppression: The system includes a sophisticated fire detection and suppression system that automatically activates if high temperatures or other anomalies are detected, preventing thermal runaway and minimizing fire risk at the source.

- Continuous Real-Time Monitoring & Alerts: Continuous monitoring of battery temperature, voltage, and overall system health allows for the early detection of any potential issues. The system can trigger alerts or perform automated shutdowns to prevent incidents before they happen, shifting safety from a reactive to a proactive model.

- Noise Reduction as a Safety Feature: A quieter worksite is a safer worksite. The silent operation of the Infinity Cube dramatically improves communication between workers, ensuring that audible warnings, alarms, and instructions are clearly heard, reducing the risk of accidents.

- Elimination of Fuel-Related Hazards: By reducing or eliminating the need for on-site diesel storage and handling, the Infinity Cube removes a significant source of risk. This includes eliminating hazards from fuel spills during refueling, potential ignition from flammable liquids, and the complex compliance issues associated with storing large quantities of fuel on site.

The Sustainability Advantage: Meeting Modern Project Demands

In today’s market, sustainability is no longer a “nice-to-have”; it is a core business imperative that directly impacts brand reputation, client acquisition, and talent retention. The Infinity Cube directly supports green initiatives, which translates into a powerful competitive advantage.

- Achieve Prestigious Green Certifications: Using a BESS is a high-impact strategy for earning valuable points toward green building certifications like LEED and BREEAM. This not only enhances a project’s environmental profile but also makes it more attractive to a growing market of eco-conscious clients and investors.

- Strengthen Community & Client Relations: The Infinity Cube produces zero on-site carbon emissions and operates silently. This is crucial for meeting strict regulatory standards in urban areas and drastically reduces noise and fume complaints from the surrounding community, leading to smoother permitting and better public relations.

- Attract Top Talent and Forward-Thinking Clients: A demonstrable commitment to cutting-edge, sustainable technology positions your company as an industry leader. This enhances your brand and makes your company more attractive to top talent and clients who want to partner with responsible, future-focused organizations.

Conclusion: More Than a Machine, A Strategic Imperative

The business case for the Infinity Cube is clear, compelling, and multifaceted. It is not merely a piece of equipment but a strategic investment that directly impacts profitability, enhances operational efficiency, mitigates operational and safety risks, and future-proofs your projects for the demands of tomorrow. By delivering significant and verifiable cost savings, streamlining complex workflows, and creating a safer, more sustainable worksite, the Infinity Cube offers an undeniable competitive advantage that is essential for thriving in the modern construction industry.