In the rugged, high-demand environments of construction and mining, reliable, efficient power isn’t a luxury. It’s a necessity. Downtime is expensive, logistics are complex, and environmental scrutiny is increasing. Enter Infinity Cube: a next-generation Battery Energy Storage System (BESS) specifically engineered for these challenging sectors. Whether you’re powering a remote quarry or a large-scale construction project, Infinity Cube delivers hybrid energy solutions that enhance reliability, reduce fuel costs, and streamline sustainability compliance.

Key Power Challenges in Construction and Mining Projects

Construction and mining operations face a unique set of energy challenges:

- Unstable Power Supply: Remote sites often lack reliable grid access, relying heavily on diesel generators.

- Costly Fuel Logistics: Transporting diesel to off-grid or remote locations is expensive and vulnerable to delays.

- Generator Downtime: Overworked or improperly sized generators lead to frequent breakdowns and productivity loss.

- High Operating Costs: Fuel waste, maintenance requirements, and inefficiency significantly increase total operating expenditure.

These pressures require a power solution that is robust, flexible, and cost-effective, especially when operational margins are tight and deadlines are strict.

Infinity Cube’s Hybrid Power Load Sharing Technology

Infinity Cube’s hybrid load sharing system is designed to solve these exact issues. By integrating advanced BESS units with conventional generators, Infinity Cube enables smarter power solutions:

- Smart Load Distribution: The system shares the load intelligently between generator and battery, ensuring that the generator runs only when needed.

- Fuel Efficiency Gains: Load sharing avoids low-load inefficiency, where generators waste fuel running below optimal capacity.

- Reduced Downtime: Batteries supply backup or supplementary power during generator maintenance or low-demand periods.

- Optimised Equipment Use: Generators operate at peak fuel efficiency, extending service life and reducing stress on components.

This seamless transition between generator and battery helps sites operate more efficiently with less fuel and fewer interruptions.

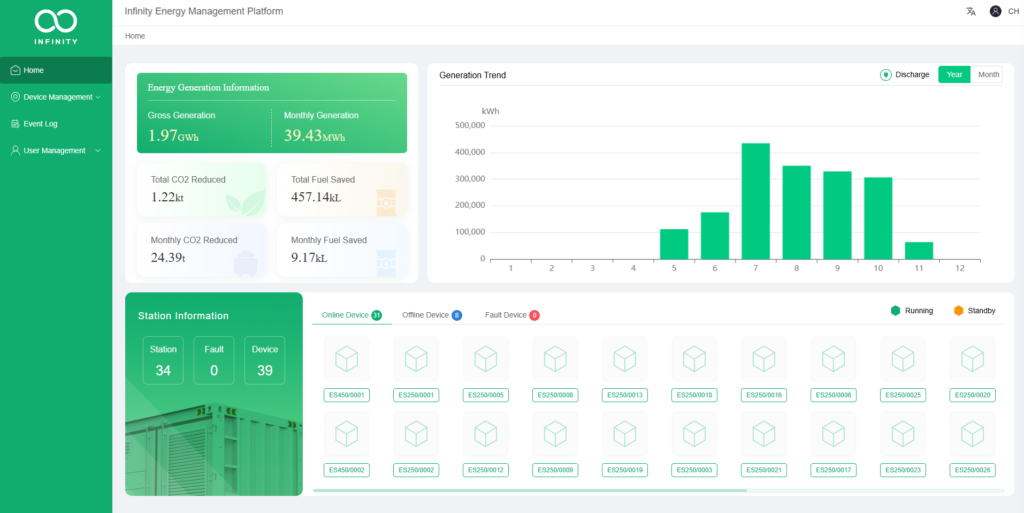

Advanced Cloud Monitoring & Remote Control

Infinity Cube isn’t just powerful, it’s also intelligent and connected. Its integrated cloud-based control platform offers:

- Real-Time Monitoring: View live energy usage, battery charge levels, fuel savings, and carbon reduction from any device.

- Predictive Maintenance: Identify issues before they cause downtime with smart diagnostics and system health alerts.

- Remote Control Capabilities: Adjust energy settings, schedule operations, and troubleshoot without needing to be on-site.

- Carbon Emissions Tracking: Automatically track emissions reductions, enabling straightforward reporting for compliance or client ESG targets.

This data-driven approach empowers construction and mining companies to optimise site performance while maintaining complete control even from headquarters or regional offices.

Lower Fuel Consumption & Maintenance Costs

Fuel and maintenance are two of the biggest cost centres in any off-grid operation.

Infinity Cube helps bring both under control:

- Reduced Generator Runtime: BESS units handle fluctuating or low demand loads, letting generators shut off or run less frequently.

- Lower Diesel Consumption: Smart load balancing means less fuel is burned per kilowatt-hour, often achieving fuel savings of up to 90% on hybrid model and 100% on grid model depending on site requirements.

- Extended Generator Lifespan: Reduced runtime and peak performance operation mean fewer breakdowns and less frequent servicing.

- Minimal Site Disruption: Fewer fuel deliveries and less generator maintenance reduce logistics headaches and environmental risk.

These benefits translate directly into reduced operational expenditure and more predictable site performance.

Compliance-Ready for Carbon Reporting and Green Mandates

As environmental regulations tighten, construction and mining companies must increasingly account for their carbon emissions. Infinity Cube helps you stay ahead:

- GHG Reporting Support: Built-in carbon tracking aligns with Scope 1 and Scope 2 emissions measurement frameworks.

- Carbon Tax Readiness: Lower emissions reduce exposure to rising carbon tax rates under Singapore’s evolving Carbon Pricing Act.

- Green Grant Eligibility: Infinity Cube is pre-approved under Singapore’s Energy Efficiency Fund (E2F), helping offset investment costs.

- Sustainability Credentials: Sites using hybrid power are better positioned in tenders with green requirements or ESG criteria.

Incorporating Infinity Cube into your energy strategy helps ensure that compliance is embedded, not bolted on.

Real-World Applications and Case Studies

Here’s how Infinity Cube is already making a difference:

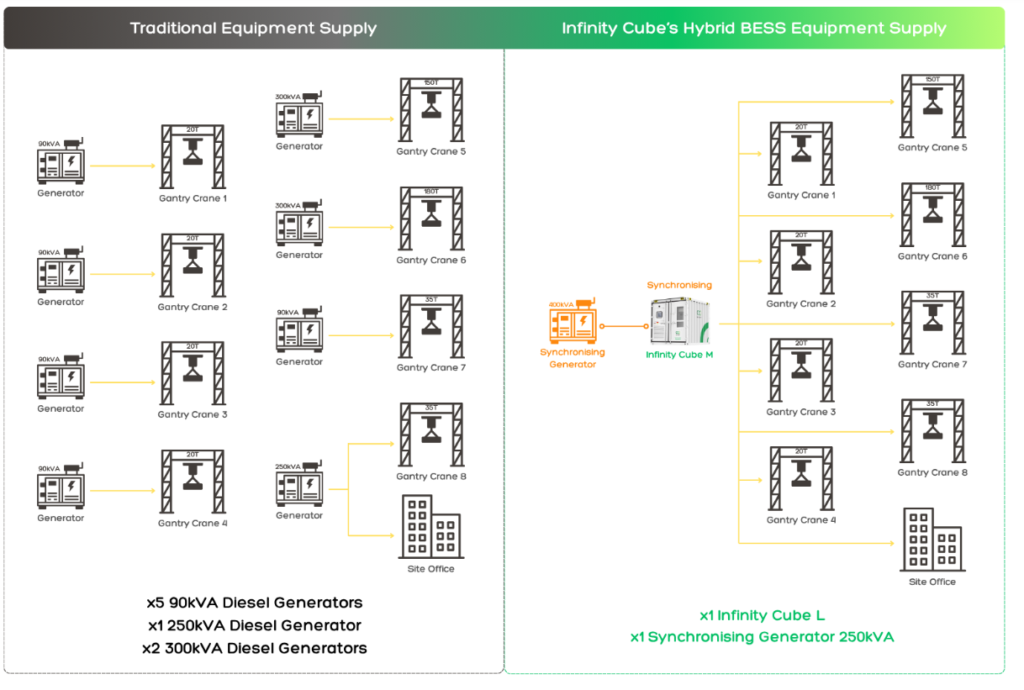

Case Study 1: Wai Fong Construction Precast Yard Project

The precast yard initially relied on a complex and inefficient traditional power system. To run multiple gantry cranes and the site office, the project used eight separate diesel generators of varying sizes (five 90kVA, one 250kVA, and two 300kVA). This decentralized setup resulted in:

- High fuel consumption, as generators were often running inefficiently at low loads.

- Significant maintenance and logistical costs for managing eight different units.

- A substantial carbon footprint due to constant diesel combustion.

Infinity Cube replaced this entire setup with a single, intelligent hybrid solution:

- One Infinity Cube L (Battery Energy Storage System)

- One Synchronising Generator (250kVA)

With this new configuration, the generator recharges the BESS and handles the low base load for the gantry cranes and other site equipment while the Infinity Cube handles moments of peak power demand. This results in a significant reduction of the number of generators on site. In this new configuration, the Infinity Cube BESS handles the primary power load for the gantry cranes and other site equipment. The generator only activates when required to recharge the battery or to assist during moments of peak power demand, ensuring it always runs at its most fuel-efficient level.

The Results: Dramatic Cost and Carbon Savings

The switch to the Infinity Cube hybrid system delivered immediate and substantial annual savings:

- Annual Fuel Savings: 288,204 Litres By eliminating inefficient generator idling and optimising power delivery, the project drastically cut its yearly diesel consumption.

- Annual Cost Savings: SGD $374,665 This massive reduction in fuel use directly translated into significant financial savings, greatly lowering the project’s overall operational expenditure.

- Annual Carbon Savings: 772,380 kgCO₂e By burning far less diesel, the project slashed its annual carbon emissions, demonstrating a strong commitment to sustainability and preparing for stricter environmental regulations.

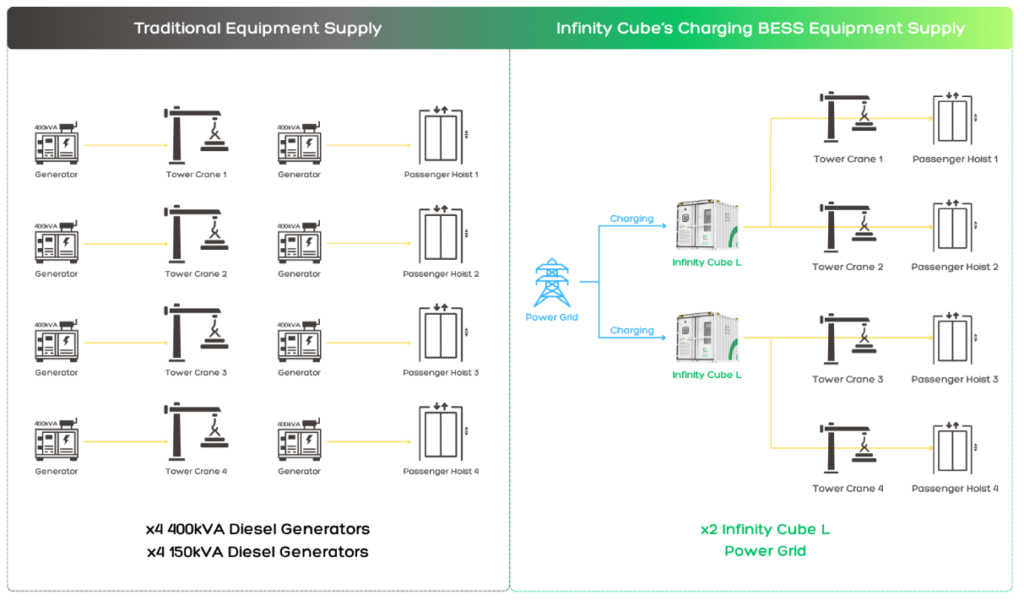

Case Study 2: TeamBuild Construction Group HDB Project

For a large HDB (Housing & Development Board) project, TeamBuild initially powered its four tower cranes and four passenger hoists with eight separate diesel generators (four 400kVA and four 150kVA). This traditional method created several problems:

- High Operational Costs from fuel consumption and continuous maintenance on eight machines.

- Significant Noise and Air Pollution, which are major concerns for construction sites located within or near residential communities.

- A Large Carbon Footprint, inconsistent with the sustainability goals of modern public housing projects.

The project underwent a complete energy transformation by replacing all eight diesel generators with:

- Two Infinity Cube L units

- Connection to the Power Grid

This innovative setup uses the main power grid to charge the Infinity Cube batteries, typically during off-peak hours. The fully charged BESS units then provide clean, silent, and stable power to all the heavy machinery throughout the workday. This approach effectively creates a zero-emission, diesel-free power source on-site.

The Results: A Complete Elimination of Fuel Costs and Emissions

By shifting from diesel generators to a grid-powered BESS, the project achieved outstanding results:

- Fuel Savings: 228,576 Litres Annually By completely removing the generators for these operations, the project’s annual diesel consumption was reduced to zero, leading to massive savings.

- Cost Savings: SGD $297,148 Annually This figure represents the total savings from eliminated fuel purchases, generator rental fees, and maintenance costs, leading to a significant reduction in operational expenditure.

- Carbon Savings: 612,582 kgCO₂e Annually Transitioning to a clean energy source drastically cut the project’s carbon footprint, aligning it with Singapore’s Green Plan and setting a new benchmark for sustainable construction.

These results prove that Infinity Cube isn’t just theoretical, it’s field-tested, and performance proven.

Conclusion: Engineered for Tough Jobs, Designed for Smart Compliance

Infinity Cube is more than a battery, it’s a fully integrated smart energy solution built for industries that can’t afford power failures, cost overruns, or compliance gaps. With load-sharing efficiency, cloud-based intelligence, and emissions-ready reporting, Infinity Cube delivers smarter, cleaner, and more resilient power for the construction and mining sectors.

Discover how Infinity Cube can power your next construction or mining project with smarter, cleaner energy. Schedule a demo today.