Why GHG Reporting is Now a Critical Compliance Issue for Singapore’s Construction & Manufacturing Sectors

Greenhouse gas (GHG) reporting has rapidly shifted from a sustainability buzzword to a legal and operational necessity especially for construction and manufacturing companies in Singapore. With tightening environmental regulations, stricter enforcement, and growing investor pressure, businesses can no longer afford to ignore their carbon footprint. Non-compliance now carries real financial risks, including penalties, tax burdens, and reputational damage.

As Singapore moves toward its Green Plan 2030 and Net Zero 2050 goals, this article serves as a simple guide to help construction and manufacturing companies understand GHG reporting requirements and how to prepare effectively, with a special focus on how Battery Energy Storage Systems (BESS), such as Infinity Cube, can simplify compliance and reduce emissions.

Understanding GHG Reporting: Scope 1, 2, and 3 Emissions

GHG emissions are categorised into three scopes under the internationally recognised GHG Protocol:

- Scope 1: Direct emissions from owned or controlled sources (e.g., fuel combustion in generators and machinery).

- Scope 2: Indirect emissions from purchased electricity, steam, heating, and cooling.

- Scope 3: All other indirect emissions that occur in the value chain (e.g., emissions from the production of purchased materials, transportation, or waste disposal).

For construction and manufacturing companies, Scope 1 and Scope 2 are the most relevant:

- Scope 1: Fuel used in heavy machinery, diesel generators, trucks, and other on-site equipment.

- Scope 2: Electricity used in factories, project sites, and temporary offices.

- Scope 3 may apply in larger organisations with extended supply chains but is currently less enforced for SMEs.

Singapore’s Regulatory Landscape: What You Must Know

Singapore’s regulatory framework for carbon emissions is evolving rapidly:

- The National Environment Agency (NEA) mandates large emitters (more than 25,000 tCO₂e annually) to report and be taxed on emissions.

- Carbon Tax: Already in effect, the tax rate will rise progressively from S$5 per tCO₂e to S$25 in 2024, S$45 in 2026, and S$50–80 by 2030.

- SGX Rules for FY2025: Listed companies must provide climate-related disclosures aligned with the Task Force on Climate-related Financial Disclosures (TCFD), including Scope 1 and 2 emissions.

Even non-listed firms and SMEs in construction and manufacturing are under increasing pressure from clients, financiers, and government bodies to demonstrate emissions transparency.

How Construction and Manufacturing Operations Generate GHG Emissions

Construction and manufacturing sites are energy-intensive environments.

Key sources of emissions include:

- Diesel generators: Used for power generation in remote or undeveloped areas.

- Heavy machinery: Excavators, cranes, loaders (all typically diesel-powered).

- Temporary site setups: Offices, lighting, and ventilation systems often run on inefficient energy sources.

- Fuel transport and usage: Repeated refuelling trips increase Scope 1 emissions and operational costs.

These sources contribute significantly to both direct and indirect emissions, driving the urgency for better energy solutions.

The Role of BESS in Cutting Emissions and Easing GHG Reporting

Battery Energy Storage Systems (BESS) offer a practical and immediate way to reduce reliance on diesel, improve energy efficiency, and simplify emissions tracking.

- Reduce Scope 1 emissions: By replacing or hybridising diesel generators, BESS significantly cuts fuel use and on-site combustion.

- Lower Scope 2 emissions: Paired with solar or grid power, BESS stores clean energy for later use.

- Simplify data collection: Pre-approved BESS units like Infinity Cube come equipped with real-time monitoring, helping automate energy and carbon reporting.

By integrating a BESS, companies not only reduce emissions but also collect precise data aligned with reporting frameworks, turning a compliance headache into a streamlined process.

Spotlight on Infinity Cube: Pre-Approved BESS Technology for Emissions Compliance

Infinity Cube is a pre-approved, plug-and-play battery energy storage system engineered specifically for construction and industrial applications in Singapore.

Key benefits include:

- NEA pre-approved for use with energy efficiency grants

- Integrated digital monitoring for real-time data

- Modular and scalable for diverse site needs

- Proven ability to provide hybrid power solutions with various power sources

Infinity Cube not only supports emission reductions, it transforms compliance into a competitive advantage.

Case Study: Diesel vs. Hybrid Setup with Infinity Cube

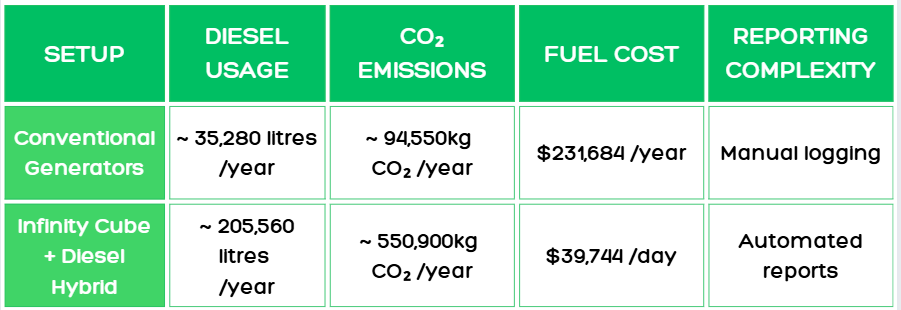

Let’s compare GHG emissions from an actual case study featuring a conventional diesel generator setup vs. a hybrid Infinity Cube system:

A standard setup relying solely on diesel generators is not only expensive but also a significant source of emissions. With an annual fuel consumption of over 35,000 litres, the setup generated approximately 94,550 kg of CO₂. The fuel costs alone amounted to over S$231,000 per year, and all energy usage had to be logged manually, creating a time-consuming and error-prone process for GHG reporting.

By integrating the Infinity Cube to create a hybrid system, the generator’s runtime was drastically reduced. The battery provided power during periods of low load and was recharged by the generator running at its most efficient peak. This change led to transformative results:

- Massive Emissions Drop: CO₂ emissions fell to just over 16,000 kg, a reduction of approximately 83%. This directly lowers the company’s carbon footprint and potential carbon tax liability.

- Significant Fuel Savings: Annual fuel usage dropped by about 82% to just 6,350 litres, resulting in annual fuel cost savings of over S$190,000.

- Simplified, Automated Reporting: The Infinity Cube’s integrated digital monitoring system automatically tracked energy consumption and calculated emissions data. This replaced manual logging with audit-ready reports, turning a complex compliance task into a simple, automated process.

- This case study demonstrates that switching to a hybrid BESS setup is one of the most effective strategies for achieving immediate financial savings and simplifying GHG reporting compliance.

Financial Payback, Grants, and Long-Term ROI

Beyond environmental benefits, BESS adoption makes financial sense:

- Government grants: Infinity Cube qualifies for EEG grants, slashing upfront costs.

- Fast ROI: Fuel savings and operational efficiency often result in payback within 36 months.

- Long-term gains: Lower maintenance costs, fewer fuel deliveries, and reduced tax liabilities.

- Sustainability alignment: Meet client requirements and national targets without restructuring operations.

Why Early Adoption Matters

Singapore’s emissions regulations are only becoming stricter. Companies that adopt emission-reduction technologies like BESS now will:

- Avoid future penalties or rushed last-minute investments

- Gain a competitive edge in tenders requiring emissions transparency

- Ensure smoother audits and stakeholder reporting

- The longer companies wait, the more expensive and urgent compliance will become.

Conclusion: GHG Reporting is Mandatory and BESS Makes It Easy

Greenhouse gas reporting is no longer optional for construction and manufacturing firms in Singapore. But with the right tools like Infinity Cube’s pre-approved Battery Energy Storage Systems, businesses can stay compliant, reduce emissions, cut costs, and contribute to Singapore’s sustainability goals.

Start simplifying your GHG reporting with Infinity Cube’s pre-approved battery energy storage systems. Contact us for a free consultation.