In today’s competitive construction landscape, profit margins are under intense pressure. Rising material prices, labour shortages, and tight project timelines are already squeezing returns, but one of the most consistent drains on profitability comes from within: operating costs. Fuel consumption, generator maintenance, equipment wear-and-tear, and avoidable downtime remain some of the most persistent cost centres on-site. For contractors and developers seeking leaner operations, hybrid power solutions like Infinity Cube offer a smarter, more cost-effective path forward.

Where Heavy Equipment Operating Costs Are Growing

Construction sites rely heavily on diesel-powered equipment and generators, which are essential but expensive to run and maintain.

Let’s break down the major areas of rising cost:

- Diesel Fuel: Prices remain volatile, and heavy equipment consumes vast quantities, especially when generators are oversized or running inefficiently.

- Generator Maintenance: Frequent servicing, oil changes, and filter replacements add up quickly, particularly when generators run non-stop.

- Equipment Repair: Prolonged or inefficient use leads to overheating, part failures, and accelerated component degradation.

- Standby Inefficiency: Generators often run even when no equipment is in use, wasting fuel and generating unnecessary wear.

- Labour and Man-Hour Losses: Power instability or breakdowns can halt operations, wasting valuable hours and throwing off project schedules.

These inefficiencies erode profit margins and increase operational risk, particularly on remote or high-demand job sites.

How Hybrid Power Reduces Fuel Consumption Significantly

The introduction of Battery Energy Storage Systems (BESS) is changing how construction sites power their operations. By integrating batteries with traditional diesel generators in a hybrid power setup, contractors can drastically reduce fuel usage.

Here’s how:

- Load Smoothing: During periods of low power demand such as overnight, during breaks, or when using light equipment, the BESS takes over, allowing generators to shut down.

- Smart Cycling: The battery charges when the generator is running efficiently, then delivers power during light-load periods, eliminating fuel waste from idling.

- Peak-Shaving: During sudden spikes in demand, the battery not only supplements the generator it also enables appropriate generator sizing, usually downsizing, preventing fuel-intensive surges.

In many cases, sites see fuel savings of up to 90% – 100%, depending on load patterns and project size. These savings are immediate and measurable, with no compromise on performance.

Lower Maintenance Costs with Smarter Load Management

Generator servicing is tied directly to hours of operation. By reducing runtime, hybrid systems extend maintenance intervals and reduce servicing costs.

Key benefits include:

- Fewer Oil & Filter Changes: With fewer operating hours, parts last longer, and consumables are used more efficiently.

- Reduced Wear-and-Tear: Generators operating at optimal loads experience less strain, avoiding overheating and premature failure.

- Longer Generator Lifespan: Operating under ideal conditions helps preserve the engine, reducing the need for expensive replacements or rebuilds.

Ultimately, less generator usage translates directly to lower ongoing costs, fewer unplanned outages, and better return on equipment investment.

Downtime Reduction Through Power Stability

Downtime is a silent profit killer, often stemming from unpredictable power supply or generator failure. Hybrid systems increase uptime and site reliability in several ways:

- Uninterrupted Power Supply: The BESS delivers clean, stable power instantly if a generator cuts out or becomes unstable during a surge.

- No Blackout Risk During Maintenance: While the generator is off for servicing, the battery continues powering essential systems.

- Smoother Power Delivery: Sensitive equipment benefits from steady voltage, reducing the risk of malfunctions or errors due to power fluctuations.

This enhanced stability keeps operations running consistently and safely, minimising disruption and avoiding the costly cascade effects of equipment downtime.

The ROI of Switching to Hybrid Power Solutions

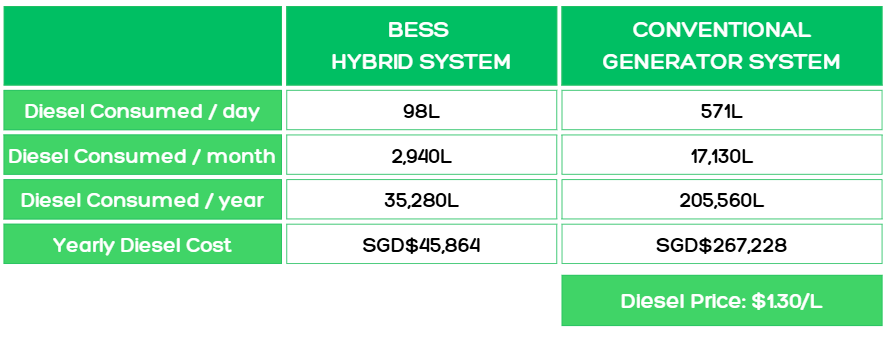

For many construction businesses, the upfront investment in hybrid systems is offset quickly by operational savings. This real-world data from an LBD Engineering HDB project provides a clear comparison.

A conventional generator system consumed 571 litres of diesel per day, costing over SGD$267,000 annually. By switching to a BESS hybrid system, daily consumption dropped to just 98 litres. This drastic efficiency gain highlights the direct impact on a construction project’s bottom line, as detailed below.

Total Annual Diesel Savings: SGD$221,364

With financing or grants available (e.g., Energy Efficiency Grant), most users achieve payback in 36 months, followed by years of continued savings and higher profitability.

Conclusion: Leaner, More Profitable Equipment Operations Start with Hybrid Power

Construction companies striving for operational excellence must address the hidden inefficiencies in their power usage. Hybrid power systems like Infinity Cube tackle key cost drivers: fuel, maintenance, and downtime by delivering smarter, more reliable energy.

With proven savings, longer equipment life, and built-in compliance support, Infinity Cube helps you run leaner and earn more from every job.

See how much you can save with Infinity Cube’s hybrid power solutions. Contact us for a personalised ROI estimate.